The Movie Star

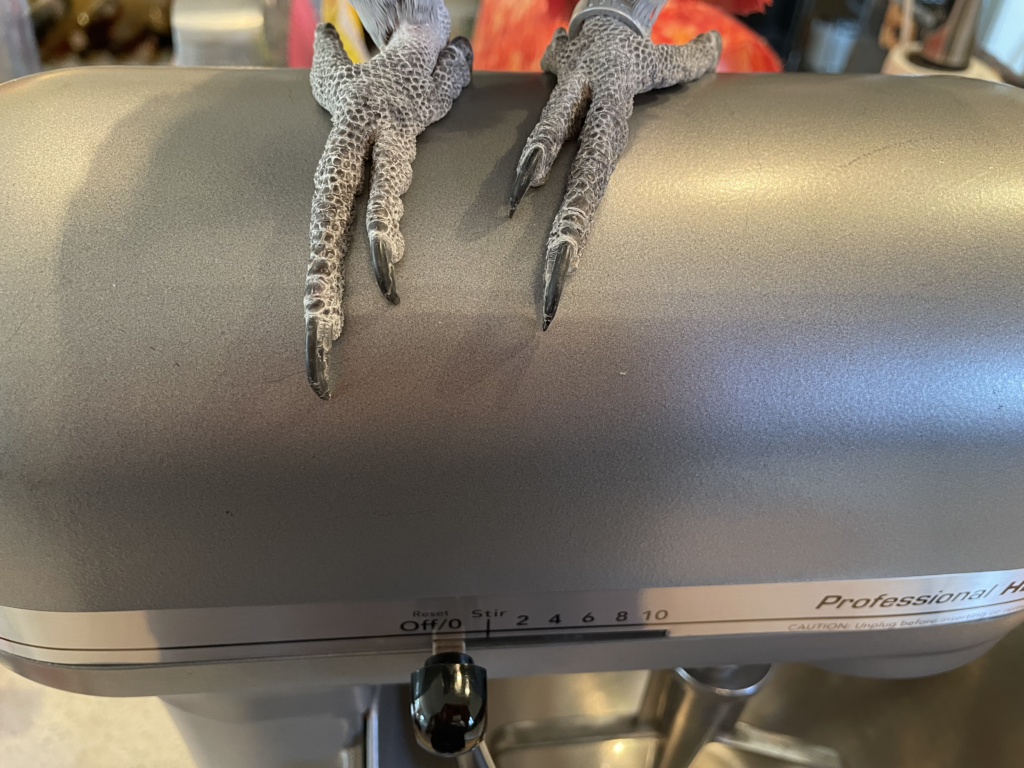

You may have seen this mixer on TV, or in a video on the Internet. Its human cares a great deal about it — they’ve been through a lot of life’s ups and downs together. Its human also has a very large audience.

One day, a friend was watching a video about this famous mixer suffering from some aches and pains. Knowing my enthusiasm for repairing KitchenAid stand mixers, he sent me a link to a video on YouTube. He said: “This is so sad!” So I started watching.

First, the mixer’s owner mentioned that the head of the machine was loose, but they hadn’t had time to deal with it. “I sent KitchenAid a message on Instagram, but they haven’t gotten back to me yet. I’ve had this machine for a very long time. I don’t want a new one; I just want to fix this one. What do I need to do?” That got my attention.

Then they went to turn the machine on, and crack — the plastic knob on the end of the speed control lever split in two. “I was just praising you! We’ve been together for a long time, and now, this breaks?!”

So, yeah: it was sad.

(Side note: One thing that really bugs me about the design of the Pro machines is that when the plastic knob cracks [which happens quite frequently on these models], there are basically two choices: try and repair the knob [which is a hit-or-miss proposition], or replace the entire speed control board assembly, which is ridiculously expensive. [$60-80, depending on where you buy it.] Ugh.)

Anyway, I contacted the producer of the video, and said (paraphrased): “Hi! I repair these things. I would be absolutely delighted to take care of your machine. Based on what I saw, here’s what I recommend. And here are some Google photo albums of work that I’ve done, and a link to a web site where I’ve been writing about this stuff. And I live not-very-far-away, so we could arrange pickup and drop-off pretty easily.”

And they wrote back! They were very happy that I got in touch and that I was willing to do the work. We exchanged details, I collected the mixer, and got it on to the bench. (And I promised to take many photos as well.)

This machine is a “Professional 5 HD”. It’s an interesting combination of attributes: the structure and drivetrain are the modern “Pro” series, with fully electronic speed control and a metal worm follower gear (which makes for a more durable drivetrain that can handle heavier loads).

At the same time, though, this model uses the old-style 5 quart bowl with straight sides, same as the original K5 that dates back sixty-odd years. The Pro 5 HD also uses the same accessories (beater, whip, and dough hook) as the K5/KSM5 series. I think that’s pretty awesome.

On to the repairs. First: floppy head.

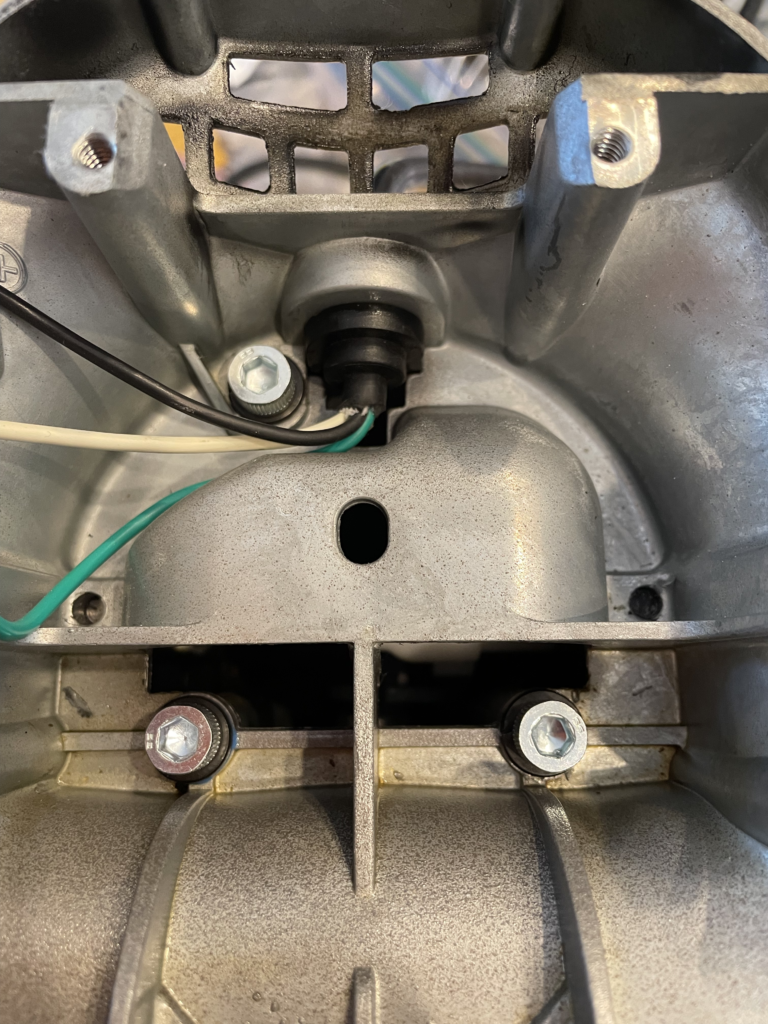

The screws holding the head onto the top had loosened up with time and vibration. Those I dealt with: new screws with hex socket heads, lock washers, and Loctite ensure that they won’t be loosening up on their own again.

Then on to the drive train maintenance. This was a natural step; in order to deal with the screws, the motor had to come out anyway, and that meant opening the gear housing. It was due for grease service. The motor shaft seal was so leaky that when the oil separated out of the original grease, the oil leaked out past the shaft seal into the body of the mixer and accumulated anywhere it could — base of the mixer, behind the trim band, you name it.

The planetary shaft was showing signs of uneven wear, and the pin which holds the gear stack in place was cracked. Whatever cracked the center pin also galled the hole in the planetary shaft which passes the pin, so I actually had to tap the planetary shaft out with a hammer.

With a cracked pin and a damaged center shaft, time for a new shaft and pin — except that, unlike the old machines, the planetary assembly is pressed together and the shaft can’t be replaced separately. So, time for a new planetary. Bleh. (This bothers me because it’s engineered that way to reduce the cost of assembly, but incurs greater expense when repairs are inevitably necessary.)

Moving on: when servicing a machine that uses the “Pro” series drivetrain, especially an older or heavily used one, I usually replace the thrust bearing on the main shaft. In this case there was a clear hint: when disassembling for cleaning, three ball bearings fell out of the thrust bearing’s race. They’re not supposed to do that.

After reassembling the mechanicals and making sure everything ran properly, I glued the knob back together (the owner wanted to keep as many original parts in service as possible, and things like that add character. Then I used gap-filling cyanoacrylate (basically, “super glue” but a little less runny) to reattach it to the lever. It seems to be holding. If it breaks again, I’ll try something else.

The rest of the job went as planned.

I took extra time to polish up the flat beater and the bowl that the customer provided. (A movie star has to look their best!)

Then to the mandatory quality-assurance checks.

I like to use the Japanese Milk Bread Rolls recipe from King Arthur Baking; it’s not super-difficult as bread recipes go, and the bread has a lovely texture and keeps for a long time. Since this is a heavy-duty machine, I doubled the batch to make it an extra-tough test. (The loaves look different because I sprinkled one with cinnamon sugar, and the other with Penzey’s Fox Point seasoning.)

And there you have it! It looks great on the outside, and works great on the inside.

If you have a technical question or think you might like me to repair your mixer, please get in touch! Any information you provide in the process of contacting me for any reason will remain private. That includes (but is not limited to) your name, location, contact information, and your mixer’s serial number.

And you, too, can get the movie-star treatment.